Recent developments at HPCAT have resulted in a number of important new experimental techniques that take advantage the properties of white beam radiation for the analysis of materials at high pressure. One such key capability is white beam radiography combined with energy-dispersive x-ray diffraction to give structural information with increasing pressure. The method is especially useful in the analysis of denisty, structure and bonding changes in amorphous materials under compression.

In new work from the CDAC group at Alabama-Birmingham, graduate student Kathryn Ham investigated the high pressure behavior of a high-boron content (17.6% B2O3) silicate glass at beamline 16-BM-B with the goal of understanding the densification process caused by applied pressure. Studies of borosilicate glasses are taking on new importance as their application as transparent armor materials is considered. The CDAC group collaborated with the Army Research Laboratory and Oak Ridge National Laboratory. At Oak Ridge, the work included complementary neutron scattering measurements.

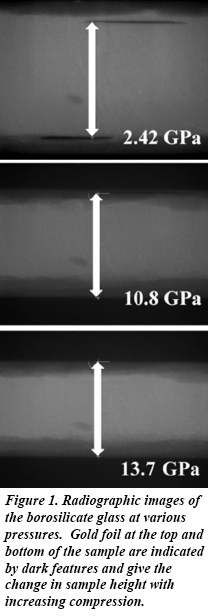

With a Paris-Edinburgh press, borosilicate glass was compressed to 13.7 GPa at room temperature. Radiographic images (Fig. 1) give the change in volume with pressure, while energy-dispersive diffraction data changes in structure and the pressure through the gold diffraction standard. The glass diffraction data are converted to give S(q) and G(r), the structure factor and the pair distribution function. In the current work, the borosilicate glass retained a residual compression of 10.6% along the loading direction upon release of pressure. G(r) data show that this densification process involves a reduction in the size of silicate rings in the glass from 5- and 6-membered rings to 4-and 5-membered rings upon compression [K. Ham, et al., High Press. Res. 37, 233-243 (2017)].